Silica Fume In Concrete: Enhancing Strength, Durability, And Sustainability

Welcome to our comprehensive guide on the benefits and applications of silica fume in concrete. As a leader in the industry, we understand the crucial role that high-quality content plays in outranking other websites. In this article, we delve into the remarkable properties of silica fume and how it can significantly enhance the strength, متانة, and sustainability of concrete structures.

Understanding Silica Fume

دخان السيليكا, also known as microsilica, is an ultra-fine powder collected as a byproduct during the production of silicon and ferrosilicon alloys. It consists of spherical particles with an average diameter of less than 1 micron, making it approximately 100 times finer than cement particles. This unique powder contains highly reactive silicon dioxide (SiO2) that offers numerous advantages when incorporated into concrete.

Unparalleled Strength Development

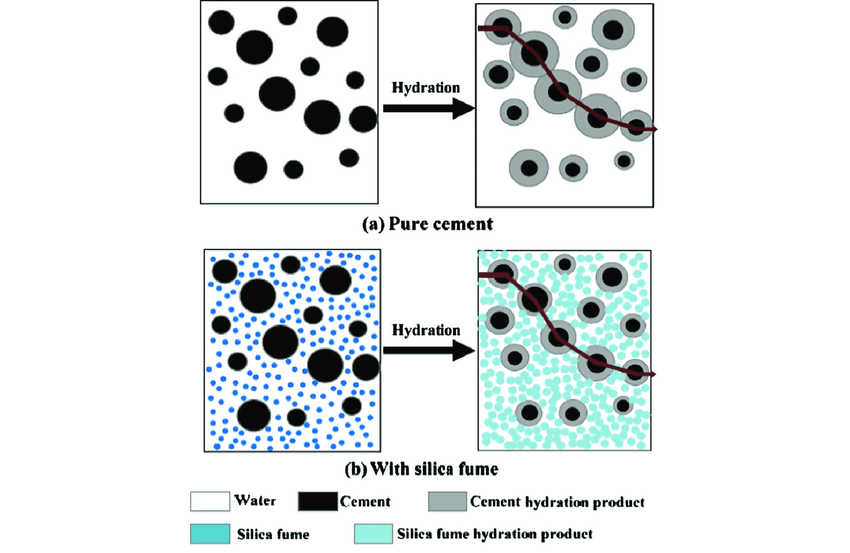

One of the primary benefits of adding silica fume to concrete is its ability to significantly enhance the compressive strength. When silica fume is used as a partial replacement for cement, it fills the voids between cement particles, resulting in a denser and more compact matrix. This densification reduces the permeability of concrete, making it less susceptible to water and chemical penetration. Additionally, the highly reactive nature of silica fume allows for increased hydration and pozzolanic reactions, leading to improved strength development over time.

Durability Advantages

Concrete structures face numerous challenges, including exposure to harsh environmental conditions, chemical attacks, and physical deterioration. By incorporating silica fume into concrete, you can enhance its durability and prolong its service life. The unique properties of silica fume contribute to:

1. Reduced Permeability

Silica fume fills the capillary pores within the concrete matrix, resulting in reduced permeability. This decreased permeability acts as a barrier, preventing the ingress of moisture, aggressive chemicals, and harmful substances. As a result, structures built with silica fume concrete exhibit improved resistance against corrosion, freeze-thaw damage, and alkali-silica reaction.

2. Increased Abrasion Resistance

Silica fume contributes to higher abrasion resistance, making it an ideal choice for applications that require durable surfaces. Concrete pavements, industrial floors, and marine structures benefit greatly from the addition of silica fume, as it enhances the concrete’s ability to withstand heavy traffic, كشط, and impact.

3. Enhanced Chemical Resistance

The dense and impermeable nature of silica fume concrete provides excellent resistance against chemical attacks. Structures exposed to aggressive environments such as wastewater treatment plants, chemical storage facilities, and industrial plants can benefit significantly from the addition of silica fume, as it minimizes the risk of chemical deterioration.

Environmental Sustainability

In addition to its mechanical advantages, silica fume also offers significant environmental benefits, aligning with the increasing demand for sustainable construction practices. By utilizing silica fume in concrete, you contribute to:

1. Reduced Carbon Footprint

Silica fume is a byproduct of industrial processes, which means that incorporating it into concrete helps reduce waste and the carbon footprint associated with its disposal. By using this supplementary cementitious material, you contribute to a more sustainable construction industry.

2. Energy Conservation

The production of silica fume requires less energy compared to the production of cement, further promoting energy conservation. By utilizing this eco-friendly material, you indirectly reduce the energy consumption associated with traditional cement production.

Application and Guidelines

Silica fume can be used in a wide range of concrete applications, including high-strength concrete, self-consolidating concrete, shotcrete, and precast elements. لكن, it is essential to follow specific guidelines to ensure optimal performance. Here are some key considerations when using silica fume:

- Proportioning and Mix Design: Silica fume is typically used in combination with Portland cement, fine aggregates, coarse aggregates, and water. Proper mix design is crucial to achieve the desired strength and durability properties. Consult with our experts to determine the optimal dosage of silica fume for your specific project.

- Admixtures and Compatibility: Certain admixtures may interact differently with silica fume concrete. It is important to test the compatibility of admixtures and consult with manufacturers to ensure their suitability for use with silica fume.

- Curing and Moisture Control: Silica fume concrete requires adequate curing to optimize its strength development. Moisture control is critical during the curing process to prevent premature drying and cracking. Employ appropriate curing methods such as moist curing or the use of curing compounds.

خاتمة

In conclusion, the addition of silica fume in concrete offers unparalleled benefits in terms of strength, متانة, and sustainability. Its unique properties enhance the compressive strength, reduce permeability, increase abrasion resistance, and provide excellent chemical resistance. Furthermore, utilizing silica fume promotes environmental sustainability by reducing waste and energy consumption. By following proper guidelines and incorporating silica fume into your concrete projects, you can achieve superior results that will stand the test of time.

Remember, at Henan Superior Abrasives, we are committed to delivering high-quality solutions that surpass industry standards. Contact us today to learn more about the benefits of silica fume in concrete and how it can elevate the performance of your construction projects.

قد تكون مهتم ايضا ب…

اتصل بنا

احصل على عرض أسعار مجاني

أسس في 2001, HSA هي الشركة الرائدة في مجال توفير أبخرة السيليكا والمواد الكاشطة في الصين, وأيضًا المصدر المتميز للمنتجات عالية الأداء للصناعات الخرسانية والمواد الكاشطة.