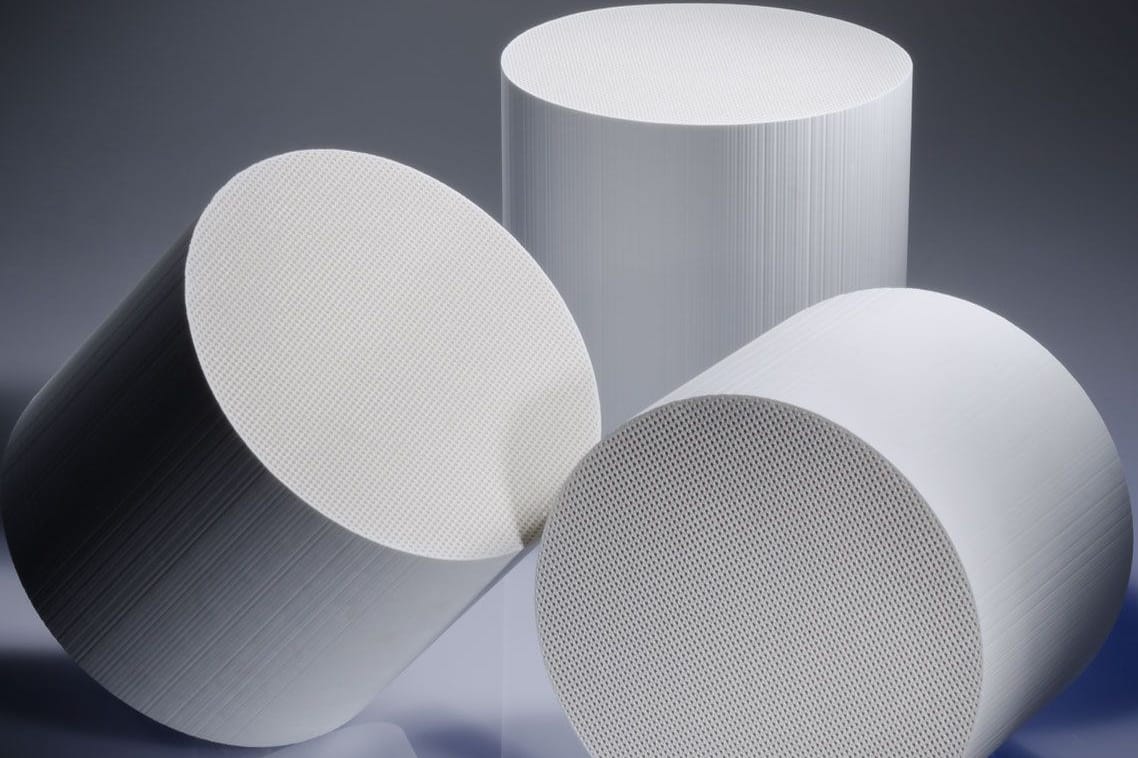

Carbure de silicium pour filtres à particules d'essence (GPF)

Dans l'industrie automobile, La réduction des émissions n'est pas seulement une exigence réglementaire; it’s a responsibility toward a sustainable future. Gasoline particulate filters (GPFs) have emerged as essential components for meeting stringent emission standards. Among the materials used for GPFs, carbure de silicium (SiC) has proven to be a game-changer. Its unique combination of thermal stability, mechanical strength, and filtration efficiency makes it the ideal choice for modern automotive applications.

Why Silicon Carbide?

Carbure de silicium is a highly durable and versatile material, known for its exceptional properties. With a melting point exceeding 2,700°C, it withstands extreme temperatures without compromising performance. This is crucial for gasoline engines, where exhaust temperatures can rise significantly during operation.

Another significant advantage of SiC is its high thermal conductivity. This property enables effective heat dissipation, preventing hotspots that could damage the filter or reduce its efficiency. Furthermore, silicon carbide’s porosity can be precisely engineered, allowing for optimal filtration of fine particulate matter (PM) while maintaining low backpressure.

Enhanced Performance in Gasoline Particulate Filters

GPFs are designed to capture and reduce particulate emissions from gasoline direct injection (GDI) engines. As engine technology advances, the demand for high-performance filters continues to grow. Silicon carbide provides the structural integrity needed to handle increased exhaust pressures and ensures long-term reliability.

When used in GPFs, SiC offers:

- Durability under cyclic thermal loads: Rapid temperature fluctuations can cause thermal shock in traditional materials, but SiC resists cracking and degradation.

- Optimized filtration efficiency: Its microstructure can trap fine particles effectively, contributing to cleaner emissions.

- Cost-effectiveness in the long term: Despite its higher initial cost, silicon carbide’s longevity and minimal maintenance requirements reduce overall lifecycle expenses.

Silicon Carbide in Action

In real-world applications, SiC-based GPFs have demonstrated superior performance across diverse conditions. Whether in urban environments with frequent start-stop cycles or on highways with sustained high speeds, these filters maintain their structural integrity and efficiency.

A prime example is their role in meeting Euro 6 and Euro 7 emission standards. Vehicles equipped with SiC GPFs consistently achieve compliance, even in markets with the most stringent regulations.

Meeting the Challenges of Modern Emission Standards

As emission regulations become increasingly demanding, automakers face significant challenges in balancing performance, efficiency, and compliance. Silicon carbide provides a solution that addresses all three aspects. Its lightweight nature contributes to overall vehicle efficiency, while its robustness ensures compliance with emission standards over the vehicle’s lifespan.

De plus, the recyclability of SiC aligns with the automotive industry’s push toward sustainable manufacturing practices. By incorporating SiC in GPFs, manufacturers not only improve vehicle performance but also reduce environmental impact.

Abrasifs supérieurs du Henan: A Trusted Partner for Silicon Carbide

At Abrasifs supérieurs du Henan (HSA), we pride ourselves on being one of China’s largest silicon carbide manufacturers. Our SiC products are engineered to meet the exacting demands of the automotive industry. With advanced production techniques and strict quality control, we deliver materials that enable superior performance in gasoline particulate filters.

Whether you’re looking for raw silicon carbide or customized solutions tailored to specific GPF designs, HSA is your trusted partner. Our extensive experience and global presence ensure that we can support your needs, no matter the scale of your operations.

Driving the Future with Silicon Carbide

Silicon carbide’s role in automotive emission control underscores its importance in the transition toward cleaner and greener technologies. As the world moves closer to a sustainable future, materials like SiC will continue to lead the way.

For automakers and suppliers seeking to stay ahead in innovation and compliance, silicon carbide for gasoline particulate filters is not just an option—it’s a necessity. Trust Henan Superior Abrasives to deliver the quality and expertise you need to drive success.

For inquiries and more information about our silicon carbide products, contact us today. Together, we can shape the future of emissions control.

- E-mail: sales@superior-abrasives.com

- WhatsApp: +86-18638638803

Vous pourriez aussi être intéressé par…

Contactez-nous

Obtenez un devis gratuit

Fondé en 2001, HSA est l'un des principaux fournisseurs de fumées de silice et d'abrasifs en Chine, et également la source premium de produits hautes performances pour les industries du béton et des abrasifs.