Reaction Bonded Silicon Carbide vs. Other Ceramics

Introduction

Ceramic materials play an indispensable role in the industrial field due to their excellent hardness, heat resistance and chemical stability. Reaction Sintered Silicon-Carbon (RB-SiC) is one of the best of the best, showing unique advantages in many demanding applications. As the world’s leading RB-SiC solutions provider, Henan Superior Abrasives will provide you with an in-depth analysis of the key differences between RB-SiC and other common ceramic materials to help you make an informed choice.

RB-SiC: a unique high-performance ceramic

RB-SiC is a silicon-carbon ceramic prepared by a unique reaction sintering process. This advanced preparation method gives RB-SiC an excellent combination of properties, including very high hardness and wear resistance, excellent thermal stability and thermal shock properties, excellent chemical inertness and corrosion resistance, and good mechanical strength and fracture toughness.

Performance Comparison: RB-SiC and Other Ceramics

Compared with traditional ceramic materials, RB-SiC exhibits a number of unique advantages.

- Hardness and wear resistance: RB-SiC’s high hardness (>25 GPa) makes it stand out in wear applications, and is much harder than materials such as alumina and silicon nitride.

- Thermal Stability: RB-SiC has an extremely high melting point (>2000°C) and is able to maintain its stability in extreme high temperature environments, which is superior to most other ceramics.

- Chemical inertness: RB-SiC has good corrosion resistance to most acids, alkalis and solvents, and is suitable for a variety of corrosive media.

- Fracture toughness: RB-SiC’s high fracture toughness makes it more resistant to impact and thermal shock, which is conducive to improving the reliability of parts.

Application Scenarios

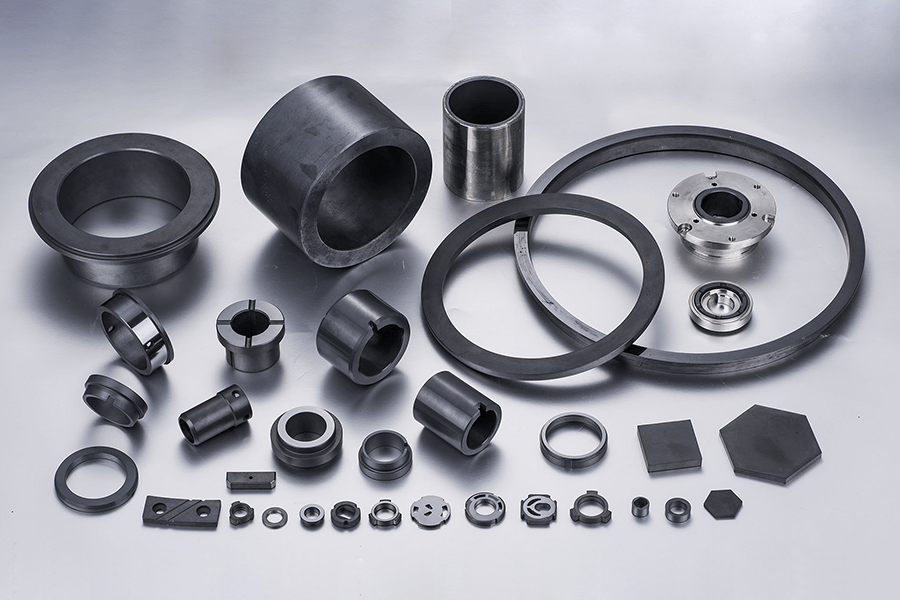

With these outstanding properties, RB-SiC plays a key role in a number of industrial applications.

- Mechanical seals: RB-SiC provides excellent sealing protection for pumps, valves and compressors, extending service life.

- Pumps, valves and pipelines: Pump casings, impellers, valves and pipeline linings made of RB-SiC resist severe wear and corrosion.

- Thermal protection: RB-SiC is widely used in high-temperature components such as rocket engines, combustion chambers and turbine blades.

- Cutting: RB-SiC excels in areas such as grinding stones, cutting tools and wear-resistant coatings.

Henan Superior Abrasives: Your RB-SiC Specialist

As a leader in the RB-SiC field, Henan Superior Abrasives has industry-leading material preparation and manufacturing capabilities, and is able to provide one-stop RB-SiC solutions from concept to mass production. Our professional team will customize RB-SiC products with excellent performance and reliable quality according to your specific application needs. Whether it’s traditional pump and valve parts and seals, or advanced thermal barrier coatings and cutting tools, Henan Superior Abrasives offers the best RB-SiC material solutions.

The Cost-Effective Choice

In addition to its outstanding performance, RB-SiC offers significant cost advantages. Compared to other high-end ceramics (e.g., silicon carbide, silicon nitride), RB-SiC has lower raw material and manufacturing costs, resulting in a better overall price/performance ratio. By cooperating with Henan Superior Abrasives, customers can not only obtain high quality RB-SiC products, but also enjoy more competitive prices.

Green and Sustainable Development

Henan Superior Abrasives attaches great importance to environmental protection and sustainable development, and our RB-SiC manufacturing process is more energy efficient and environmentally friendly. Our RB-SiC manufacturing process is more energy efficient and environmentally friendly. Compared to the traditional sintering process, the reactive sintering method consumes less energy and produces lower emissions. In addition, due to the superior wear resistance and longevity of RB-SiC products, resource wastage and production of environmentally friendly emissions can be minimized.

Conclusion

Whatever your industry sector, Henan Superior Abrasives has a unique RB-SiC solution for you. When you choose Henan Superior Abrasives’s RB-SiC products, you’re choosing superior performance, cost-effectiveness, and green credentials. Contact our team of experts today to start your RB-SiC wear resistance journey!

- Email: sales@superior-abrasives.com

- WhatsApp: +86-18638638803

- No.68 Zhengtong Road, Zhengzhou, Henan, China

You might also be interested in…

Contact Us

Get Free Quotation

Founded in 2001, HSA is a leading provider of Silica Fume and Abrasives in China, and also the premium source of high-performance Products for concrete and abrasives industries.