What is Silica Fume/Microsilica?

Basic Characteristics

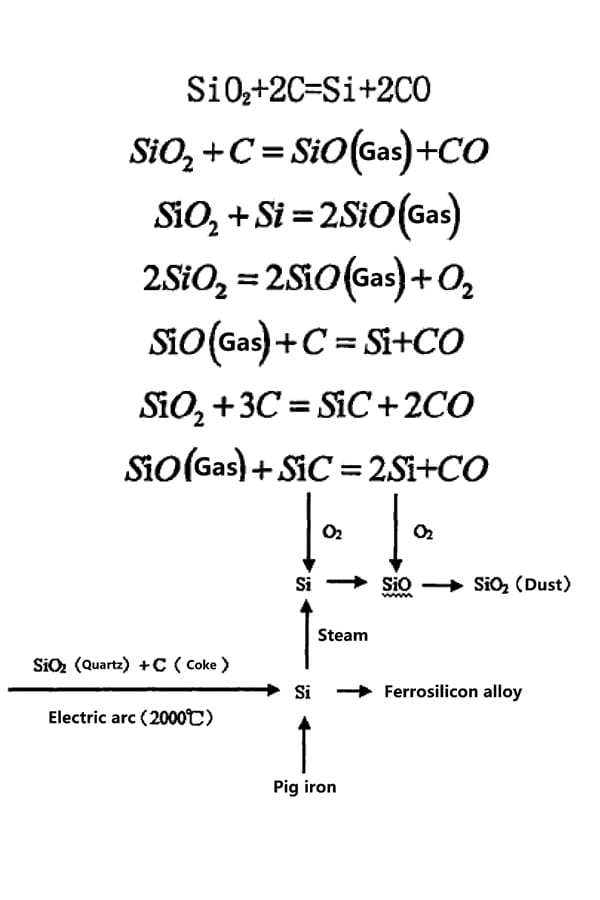

Microsilica/Silica Fume, also known as condensed silica fume, is a by-product of industrial silicon or ferrosilicon alloy smelting process. In the high-temperature electric arc furnace, silica (SiO₂) is reduced by carbonaceous reductant to generate silicon metal at the same time, a large number of gaseous SiO and Si are volatilized, and these gases are rapidly oxidized and condensed after contacting with the oxygen in the air to form a silica powder with a very fine particle size, which is recovered by the dedusting equipment as silica fume.

Core Characteristics

Chemical composition: the main component is amorphous silicon dioxide (content 85%-98%), with a small amount of sodium oxide, calcium oxide, aluminum oxide and other impurities.

Physical properties:

- Average particle size 0.1-0.3 micron, more than 85% of particles less than 1 micron, specific surface area as high as 15,000-36,000 m²/kg (about 70-90 times that of cement).

- Low density (about 200 kg/m³), need to be encrypted to improve transportation convenience.

- Color is mostly off-white, slightly darker with high carbon content.

Difference with silica powder

Silica fume is a by-product of smelting, while Silica Powder is mostly processed from natural quartz, with larger particle size (200-10,000 mesh) and higher silicon content (e.g. H-series Silica Powder reaches more than 99%), both of them are cross-cutting in application fields but with different performance focus.

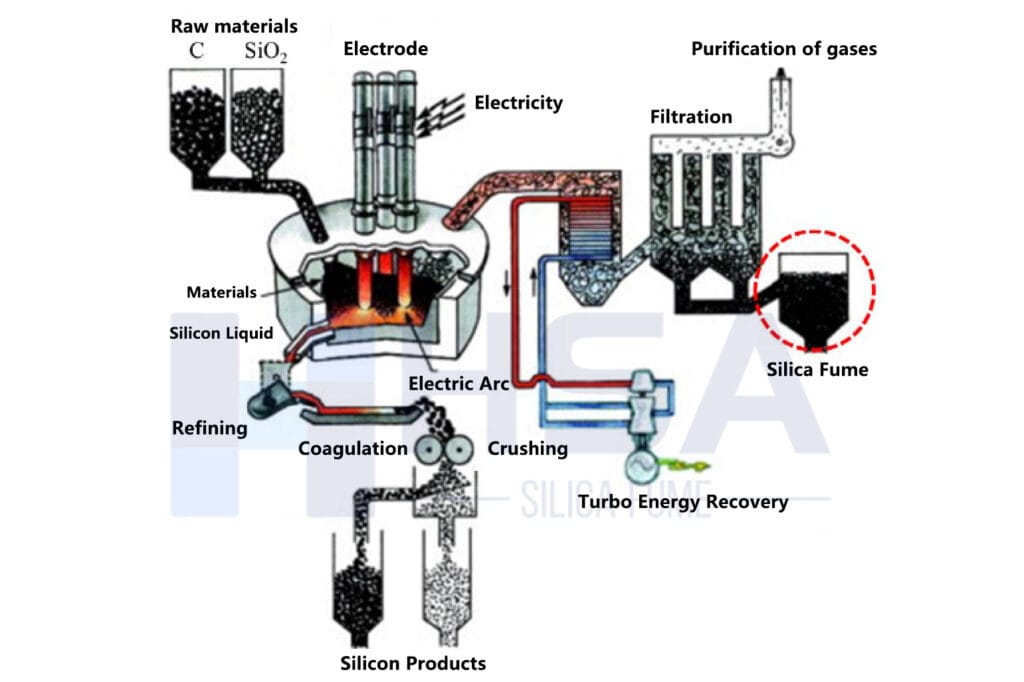

The production process of silica fume

The generation and recovery of silica fume involves the following key steps:

- Smelting process: In ferrosilicon or industrial silicon production, silica reacts with carbonaceous reductant in an electric furnace to generate gaseous SiO and Si.

- Oxidative condensation: The gaseous material is discharged and reacts with oxygen to form SiO₂, which is quenched to form ultrafine amorphous particles.

- Environmentally friendly recycling: Dust is collected through baghouse dust collector, encrypted and processed to become commercialized silica fume.

Production Challenges

China’s potential resources of silica fume are about 400,000 tons per year, but some enterprises lack recycling devices leading to resource waste and environmental pollution.

The core advantages of silica fume

Volcanic ash activity: amorphous SiO₂ can react with cement hydration product Ca(OH)₂ to generate high-strength calcium silicate gel, which significantly improves the densification of the material.

Filling effect: ultra-fine particles fill the pores of the material, reducing permeability and enhancing wear resistance.

High-temperature stability: the refractoriness reaches more than 1600℃, suitable for high-temperature environment.

Densified Silica Fume

Undensified Silica Fume

Silica fume is widely used in the field

Construction engineering

- High-strength concrete: after adding silica fume, the compressive strength can reach 70-120 MPa, which is used for high-rise building load-bearing structure, high speed rail precast parts, etc.

- Impact and abrasion-resistant concrete: the abrasion-resistant ability of the spillway hole of hydropower station, dissipating pool and other parts is improved by more than 3 times, and the service life is extended.

- Sprayed concrete: reduce rebound rate by 30%-50%, enhance tunnel construction efficiency.

Refractory materials

- The life span of castables with silica fume is increased by 3 times and refractoriness is increased by 100℃, which is used in steel ladle, coke oven and ceramic kiln.

- Combined with alumina, it generates mullite phase and enhances thermal shock resistance.

Chemicals and new materials

- Rubber and plastics: Enhance tear resistance, aging resistance, reduce material density.

- Coatings and inks: Enhance abrasion resistance, weather resistance, reduce the amount of resin.

- Electronic encapsulation: used in integrated circuit plastic sealing materials, reduce the coefficient of thermal expansion, improve insulation.

Environmental protection and agriculture

- Well cementing and sewage treatment: improve the stability of cement slurry in oilfield well cementing, adsorption of heavy metals in sewage treatment.

- Agricultural fertilizer: prevent caking, promote soil silicon element cycle.

Environmental value of silica fume

As a by-product of smelting, the recycling of silica fume not only reduces dust pollution (hundreds of thousands of tons of emission reduction per year), but also reduces the amount of cement used in concrete (10%-20%) and reduces carbon emissions. For example, 1 ton of silica fume can replace 3-5 tons of cement, and at the same time, enhance the life span of the project, thus realizing the “double environmental protection benefits”.

About HSA: China’s Leader in silica fume Industry

As one of the largest suppliers of silica fumes in China, HSA (Henan Superior Abrasives) is always committed to providing high-quality and stable silica fume products:

- Technical Advantage: Adopting fully enclosed dust removal process, the product SiO₂ content reaches 92%-94%, and the impurity content is lower than the industry standard.

- Application support: Provide customized solutions for customers, covering 20+ industries such as concrete, refractory, chemical and so on.

- Sustainable development: Recycling silica fume over 100,000 tons per year, equivalent to reducing carbon emissions by 150,000 tons.

Act now to open cooperation!

Whether it’s a large infrastructure project or a precision electronic package, HSA’s silica fume can empower your products.

- Contact us: Visit the official website https://hsachn.com/microsilica for free samples and technical consultation.

- Customized service: Adjust particle size, purity and packaging solutions according to your needs.

You might also be interested in…

Contact Us

Get Free Quotation

Founded in 2001, HSA is a leading provider of Silica Fume and Abrasives in China, and also the premium source of high-performance Products for concrete and abrasives industries.