Alúmina fundida negra

Black Fused Alumina es un material abrasivo altamente duradero y versátil que tiene una amplia gama de aplicaciones en diversas industrias. Su combinación única de propiedades físicas y químicas lo hace adecuado para la explosión abrasiva, preparación de la superficie, pulido, materiales refractarios, y aplicaciones de pisos antideslizantes. Su alta durabilidad, Baja generación de polvo, versatilidad, y la rentabilidad lo convierte en una opción ideal para los procesos industriales.

Solicitar cotización personalizada

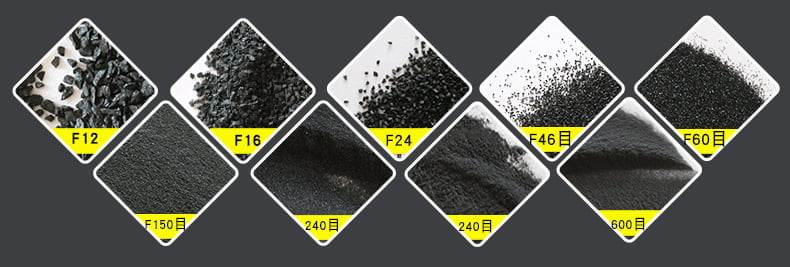

Tamaño de partícula

- Tamaño de partícula común de materiales refractarios: 0-1, 1-3, 3-5, 5-8mm, 100, 200, 325 malla

- Tamaño común de partículas de abrasivos: 12, 14, 16, 24, 30, 36, 46, 60, 80, 100, 120, 150, 180, 200, 220, 240, 280, 325 malla.

- Microperwder común para pulir y moler: 400, 600, 800, 1000, 1500, 2000, 3000 malla

- La granularidad del producto se puede procesar de acuerdo con la granularidad requerida por el usuario.

Características

- Estructura cristalina

La alúmina fusionada negra tiene una estructura cristalina hexagonal y está compuesta de aluminio, hierro, y oxígeno. El contenido de hierro le da al material su color negro. - Dureza y dureza

La alúmina fusionada negra tiene una calificación de alta dureza de 9 en la escala de mohs, haciéndolo un material adecuado para moler y pulir superficies duras. Al mismo tiempo, El material exhibe una excelente dureza, lo que le permite resistir un alto impacto y presión sin romperse. - Punto de fusión

La alúmina fusionada negra tiene un alto punto de fusión de alrededor de 2.050 ° C, haciéndolo un material resistente al calor adecuado para aplicaciones de alta temperatura.

Aplicaciones

- Explosión abrasiva

La alúmina fusionada negra es un material abrasivo popular utilizado en la explosión abrasiva. Su alta dureza y dureza lo hacen efectivo para eliminar la óxido, pintar, y otros recubrimientos superficiales de las superficies metálicas. También se usa para la preparación de la superficie antes de pintar o recubrir, ya que crea una superficie rugosa que promueve la adhesión. - Preparación de la superficie

Además de la explosión abrasiva, La alúmina fusionada negra también se usa para la preparación de la superficie en varias industrias. Se usa para ruge y limpia superficies de diferentes materiales., incluyendo metales, cerámica, y compuestos. La preparación de la superficie con alúmina fusionada negra mejora la adhesión y la unión de recubrimientos posteriores, como pinturas y selladores. - Pulido y lappiendo

La alúmina fusionada negra también se usa como material abrasivo para pulir y lamer aplicaciones. Su alta dureza y su tamaño de partícula uniforme lo hacen efectivo para lograr un acabado superficial liso y uniforme en los metales, vaso, y cerámica. Se usa comúnmente en la producción de lentes ópticas., componentes electrónicos, y piezas de precisión. - Materiales refractarios

La alúmina fusionada negra es un material refractario con excelente estabilidad de alta temperatura y resistencia química. Se utiliza en la producción de materiales refractarios como ladrillos., Cáscara, y refractarios monolíticos. Estos materiales se utilizan en la construcción de hornos., hornos, y otras aplicaciones de alta temperatura. - Piso antideslizante

La alúmina fusionada negra también se usa en la producción de materiales de pisos antideslizantes. Su alta dureza y durabilidad lo convierten en un material ideal para crear superficies resistentes a la deslizamiento en varias aplicaciones, incluyendo pisos industriales, escaleras, y pasarelas.

Parámetros

| Artículo | Indicadores |

| Color | Negro |

| Cristal | Sistema trigonal |

| Dureza(mohs) | >= 9.0 |

| Punto de fusión(℃) | 2050 |

| La temperatura máxima | 1850 |

| Verdadera densidad(g / cm3) | >= 3.50 |

| Coeficiente de expansión lineal(0-1600℃) | 7-9 |

Preguntas más frecuentes

Contáctenos

Obtenga una cotización gratuita

Fundado en 2001, HSA es un proveedor líder de abrasivos y humo de sílice en China, y también la fuente premium de productos de alto rendimiento para las industrias del hormigón y los abrasivos..